This One ring does not rule them all. 🙁 The connections are all good now on the angle sensor PCB but during testing I was getting this error when I put the PCB in the housing and rotated the shaft of the windvane:

Magnetic field too weak

Magnetic field too  weak

weak

Magnetic field too weak

Magnetic field too weak

angle = 55

angle = 36

angle = 311

Magnetic field too weak

Magnetic field too weak

Magnetic field too weak

angle = 154

angle = 153

angle = 101

angle = 212

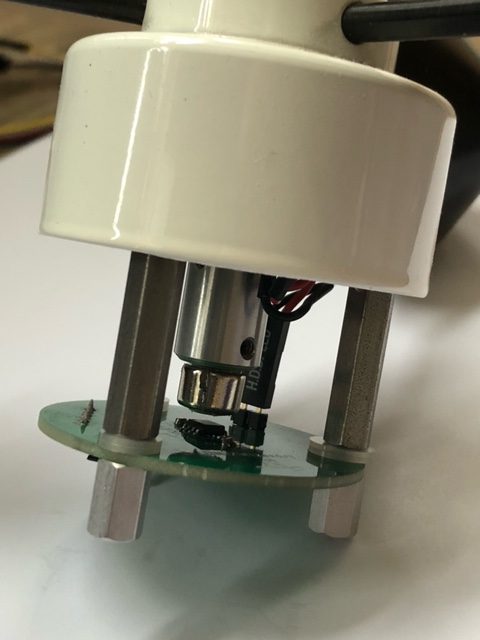

Apparently, I thought I could patch together the ring-style magnet that I inadvertently broke as I was putting it back with the other STRONG magnets. But they just rapidly snapped together, breaking the ring magnet in half. (See my post here about the magnets.) And because it wasn’t a continuous and uniform magnet, I was getting the “Magnetic field too weak” message from my test program. You can see the break in the ring magnet in this picture below that I took. I did see this error earlier in my tests but thought it might be the magnet placement. Nope. a GOOD diametrically magnetized magnet works pretty much NO MATTER how it is located. (As long as it’s not too far from the sensor.) So, good thing I have another one to use! So, a little silicone seal to hold the post and it should be good. Hopefully no more obstacles to finally getting this anemometer project done!